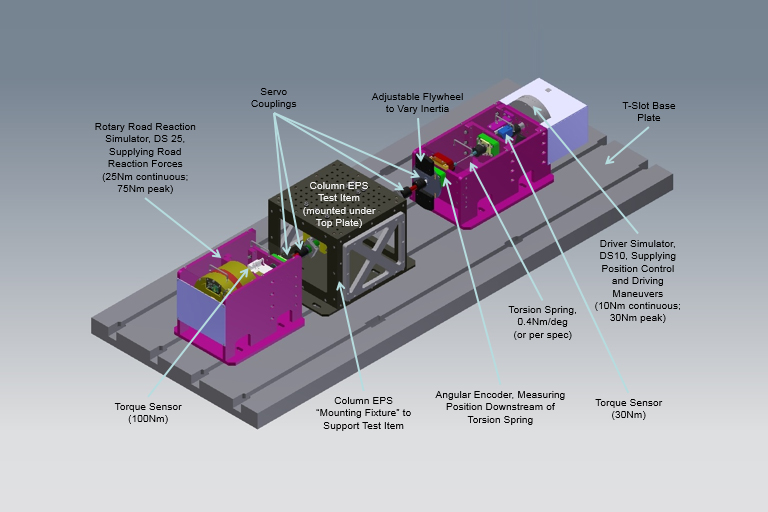

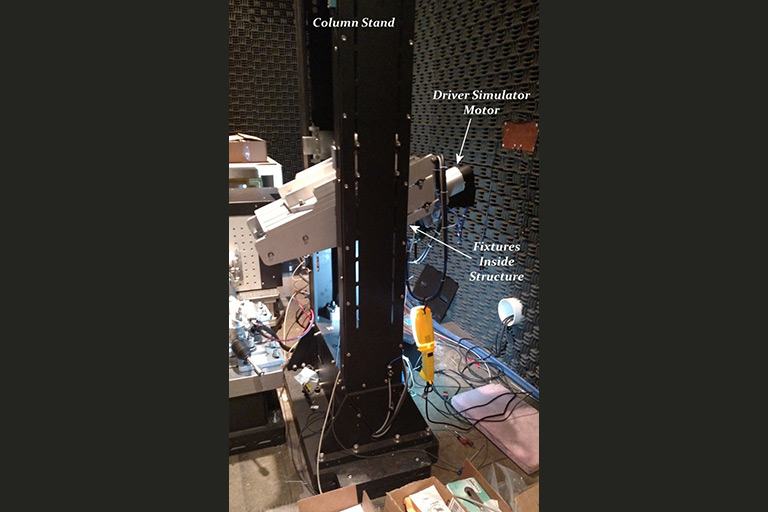

MB provides a Column Stand for mounting a steering column assembly, column EPS, and or a Driver Simulator. The steering column attaches to this Column Stand using MB-supplied, or end-user supplied, brackets at the same structural connect points where the column attaches in the vehicle.

Data Sheets

The Column Stand also comes with a fixture for mounting the Driver Simulator (DS10, DS25, or DS50) and connecting it to the column. The Column Stand assembly allows space and provision for mounting (or removing) a Driver Simulator, for using or not using bolt-on inertias to replicate different steering wheels, for installing a rotating torque sensor, for mounting steering wheels to the column spline (with Driver Simulator removed), and for using or not using a rotational spring to de-couple the inertia of the Driver Simulator. To mount the column and I-shaft in their in-vehicle positions and angles, MB provides adjustment of the column and Driver Simulator mounting fixtures in the vertical (Z-axis), fore-aft (X-axis), lateral (Y-axis), and tilt or rotation about the Y-axis. Height (Z-axis) adjustments are via a motor drive. Mobility on top of a T-slot base plate by one person is available using MB-supplied air lifters, requiring only a small amount of air to levitate about 3mm.

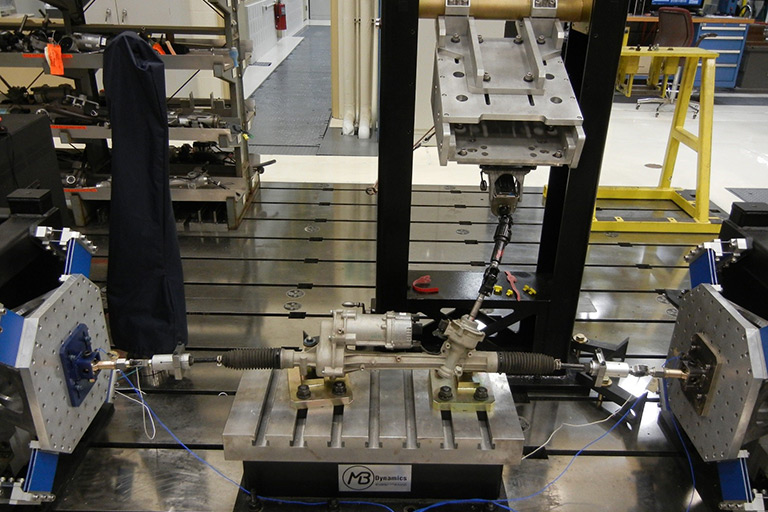

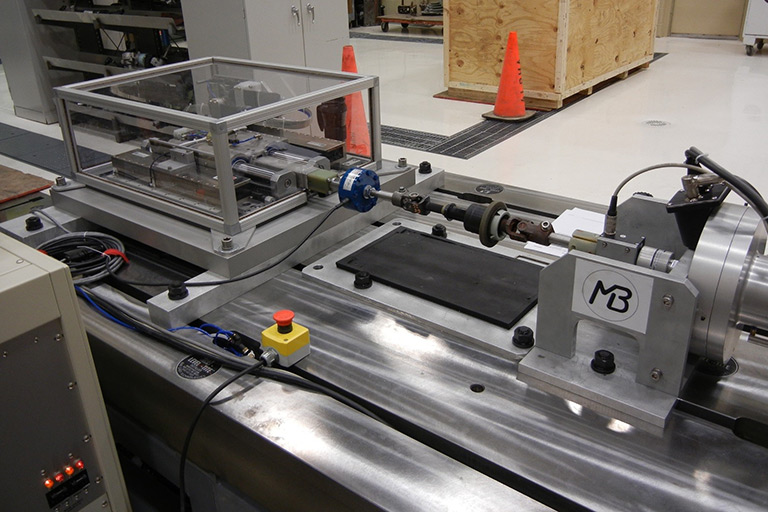

MB provides a Steering Gear Fixture or rack stand for mounting the gear using a stiff, heavy T-slot design weighing 350kg. Different sizes can be provided but this standard MB configuration is 815mm Long x 381mm Wide x 341mm High which provides for varying heights of gears and for different sized brackets or adapters depending on the geometry of the gear. It is sized to mount the centerline of the tie rod / steering gear at 441mm above top of T-slot table surface to align with the rack rattle lever arm and center of Jounce / Rebound / Fore-aft Excitation Fixture.

Our Engineer and Sales Teams are Standing By

Ready to take delivery of steering test software & hardware? Pre-sale or engineering questions?

Explore MB Dynamics' Complete Line of Steering Test Software & Hardware

MB Dynamics delivers steering test equipment to help fulfill a myriad of application test requirements, or jobs-to-be-done.

A quiet (acoustically and electrically), non-hydraulic, turnkey lab test system.

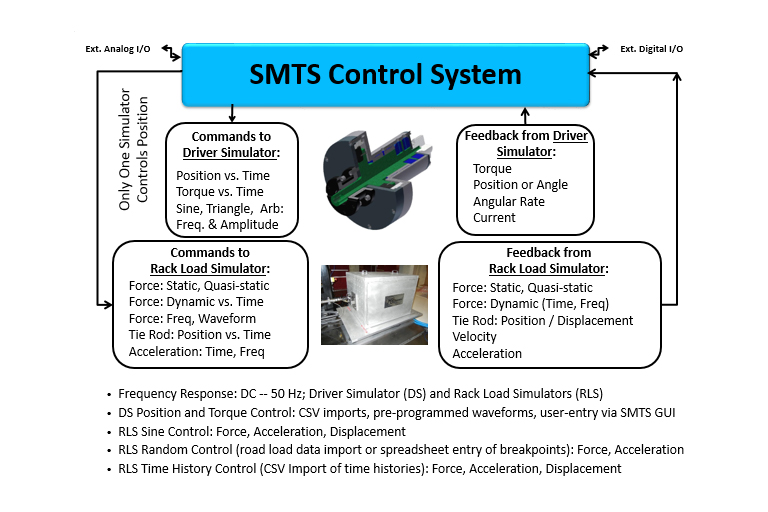

Provides an executive function over the embedded control systems for the MB DS and the two MB RLSs.

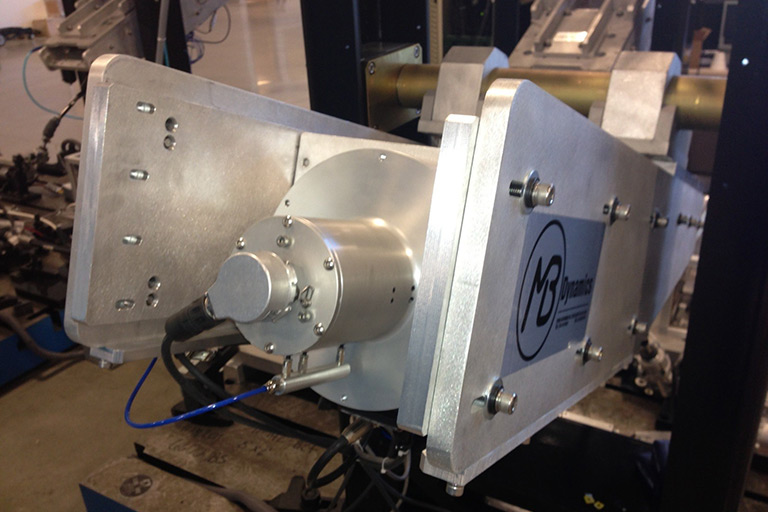

Simulates driver functionality by generating repeatable and precise steering maneuvers.

Quietly produces accurate, controlled, inputs to the in-vehicle steering wheel to enable acquisition of acoustic data and wheel motions

Electric, electrodynamic or pneumatic devices that apply programmable static, quasi-static and dynamic loads to one or both tie rods

As a variant on a SMTS, our Column EPS Test Bench is a quiet, turnkey lab test system.

Used to evaluate stick-slip, lash, torsional stiffness, hysteresis and other performance characteristics.

Provides a column stand for mounting a steering column assembly, column EPS, and or a Driver Simulator.