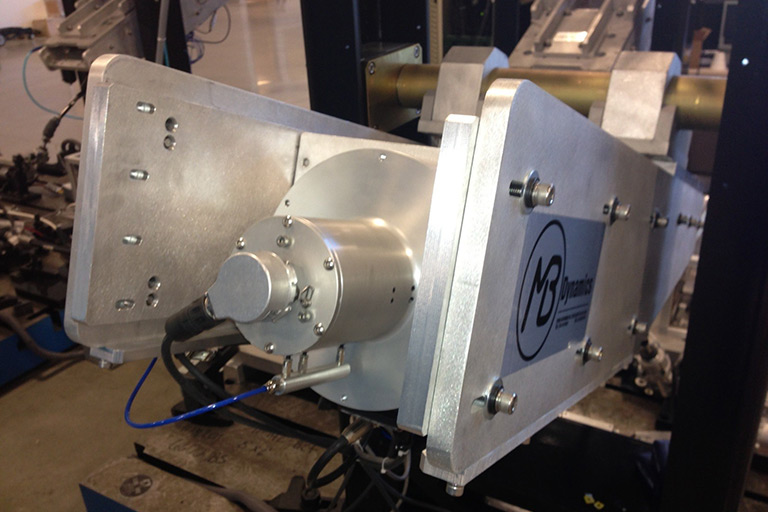

The MB Driver Simulator product family is used to simulate driver functionality by generating repeatable and precise steering maneuvers of position/angle, angular rate, or torque using imported time histories of measured drive files or user-customizable sine, triangle, and trapezoid waveform plus CSV-imported position vs. time and torque vs. time.

Data Sheets

Continuous torque outputs range are 10N-m for a DS10, 25N-m for the DS25, and 50N-m for a DS50 with peak torques 3x the continuous rating. Position resolution is excellent using an encoder with better than 1,024,000 counts per 360 degrees or 0.00035 deg/ count of resolution. This is important for low noise motions and waveform purity. Rotating torque sensors can be installed in-line. Driver Simulators are controlled with a laptop or the test rig PC in a SMTS.

The slotless design of these Driver Simulators avoids cogging or torque fluctuations and enables smooth motion without acoustic disturbances or contamination of the waveform quality caused by lower-cost slotted servos with significant cogging. Driver Simulators are direct-drive so there are no gears or belts which translates to smooth motion. Frictionless porous-media air bearings enable high accelerations and an extremely low operating background noise.

Background Noises measured with a 0.025 kg-m^2 inertial payload (no steering column/rack attached) are a measure of Driver Simulator noise that can mask steering column/rack noises. For a 90 RPM, ±500 degree move noise levels measured are <25 dB(A) over the 20Hz – 20kHz audio bandwidth when the @RestReady noises are <23 dB(A). Driver Simulators can be used standalone or in conjunction with Rack Load Simulators. A Driver Simulator may also be used for other applications which require coordinated control of torque, position and acceleration. A Driver Simulator can be used to apply rotary motion to a column connected via an I-shaft and connected to a rack that is being simultaneously excited with road vibrations.

Our Engineer and Sales Teams are Standing By

Ready to take delivery of steering test software & hardware? Pre-sale or engineering questions?

Explore MB Dynamics' Complete Line of Steering Test Software & Hardware

MB Dynamics delivers steering test equipment to help fulfill a myriad of application test requirements, or jobs-to-be-done.

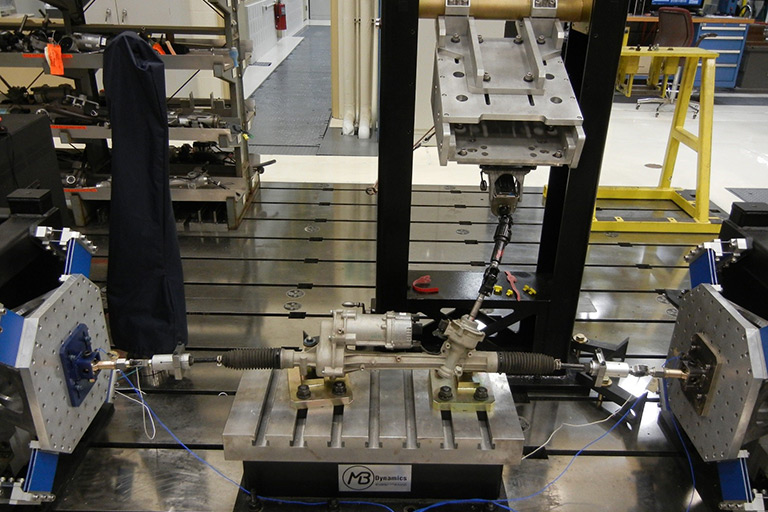

A quiet (acoustically and electrically), non-hydraulic, turnkey lab test system.

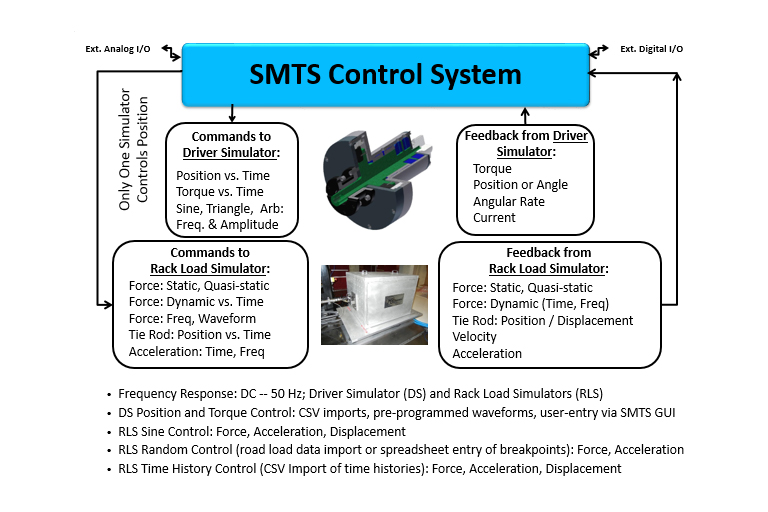

Provides an executive function over the embedded control systems for the MB DS and the two MB RLSs.

Simulates driver functionality by generating repeatable and precise steering maneuvers.

Quietly produces accurate, controlled, inputs to the in-vehicle steering wheel to enable acquisition of acoustic data and wheel motions

Electric, electrodynamic or pneumatic devices that apply programmable static, quasi-static and dynamic loads to one or both tie rods

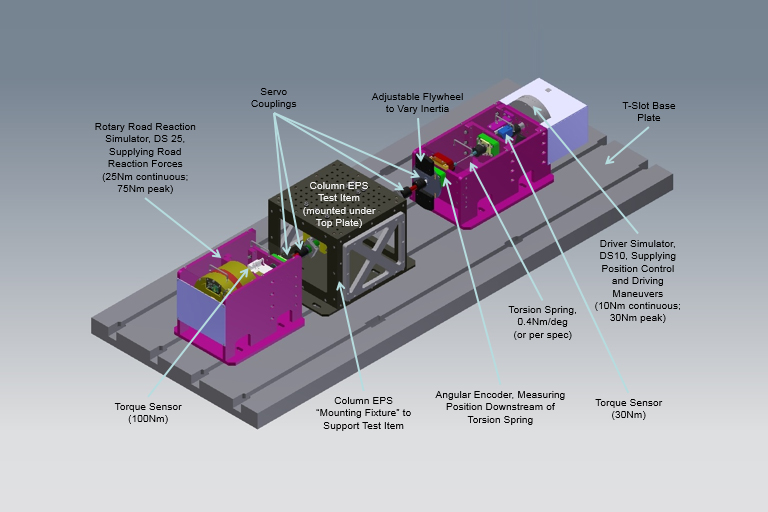

As a variant on a SMTS, our Column EPS Test Bench is a quiet, turnkey lab test system.

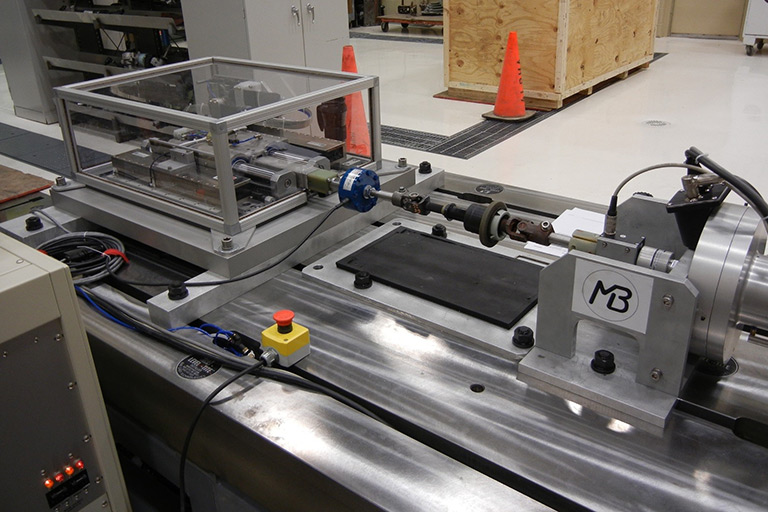

Used to evaluate stick-slip, lash, torsional stiffness, hysteresis and other performance characteristics.

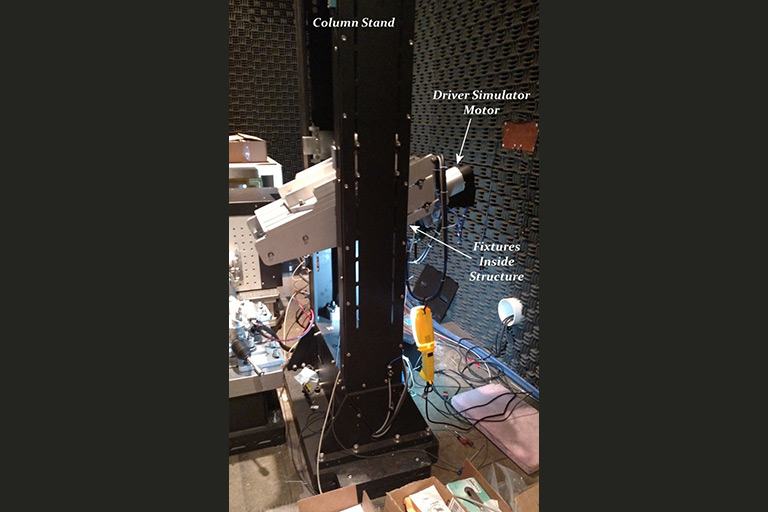

Provides a column stand for mounting a steering column assembly, column EPS, and or a Driver Simulator.