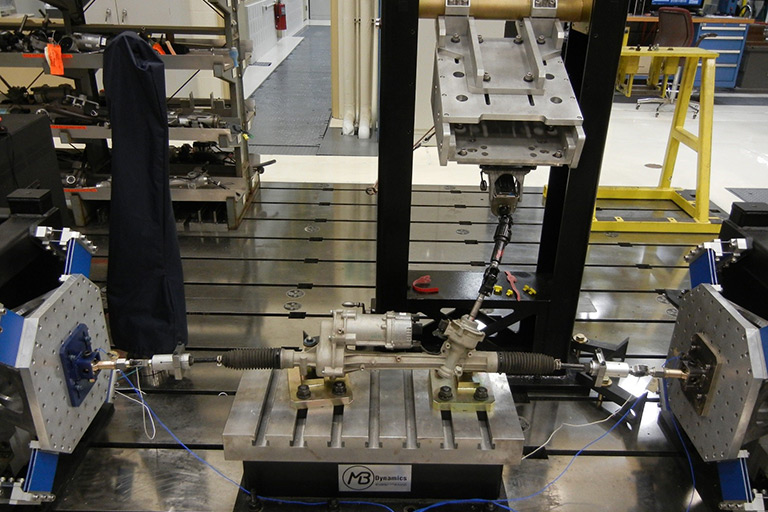

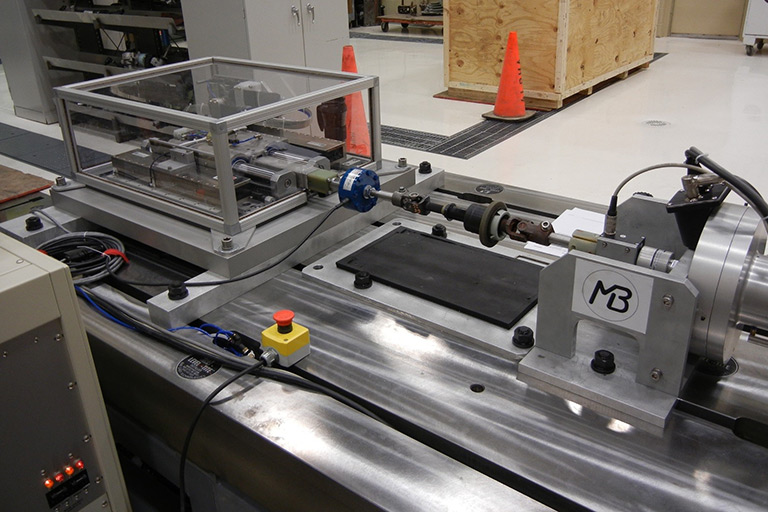

Rack load simulators (RLSs) are electric, electrodynamic or pneumatic devices that apply programmable static, quasi-static and dynamic loads to one or both tie rods (synchronized with each other), delivering force vs. steering wheel/column position or force vs. time (force time histories) under closed-loop MIMO control.

Data Sheets

RLSs replicate road and vehicle inputs acting on steering gear tie rods (single or double-ended) for rattle and performance tests under synthesized waveforms or measured road load conditions. RLSs are used for in-lab replication of rack rattle, zipper, reversal clunk, clatter, howl and growl, etc. and other running and functional noises commonly heard in the vehicle.

The repeatable reproduction in the lab of real driving conditions like lane-change maneuvers, pothole-type transients, cornering events, impacts, critical road surfaces or synthesized events that accentuate gear annoying noises help to identify, diagnose and resolve their root causes. MB RLSs are quiet so acoustic measurements can be performed as well as using acceleration recordings correlated to in-vehicle noise measurements. RLSs can be used to condition or wear gears and other components in the lab to accumulate accelerated customer-equivalent kilometers (life cycle assessment) so that rattle and NVH performance can be on the same test equipment before and after simulated customer usage.

RLS choices include: electrodynamic exciters with 2:1 and 3:1 force multiplying lever arms, direct-drive linear motors, and air spring actuators. Static and dynamic force output, frequency response, peak-to-peak stroke, background noise levels, force slew rates, and cost are factors to consider and trade-off in selecting the right RLS for a particular application.

Our Engineer and Sales Teams are Standing By

Ready to take delivery of steering test software & hardware? Pre-sale or engineering questions?

Explore MB Dynamics' Complete Line of Steering Test Software & Hardware

MB Dynamics delivers steering test equipment to help fulfill a myriad of application test requirements, or jobs-to-be-done.

A quiet (acoustically and electrically), non-hydraulic, turnkey lab test system.

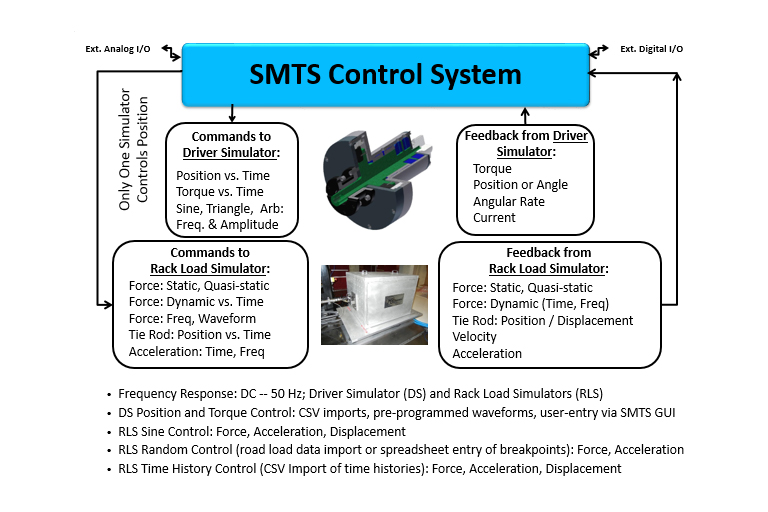

Provides an executive function over the embedded control systems for the MB DS and the two MB RLSs.

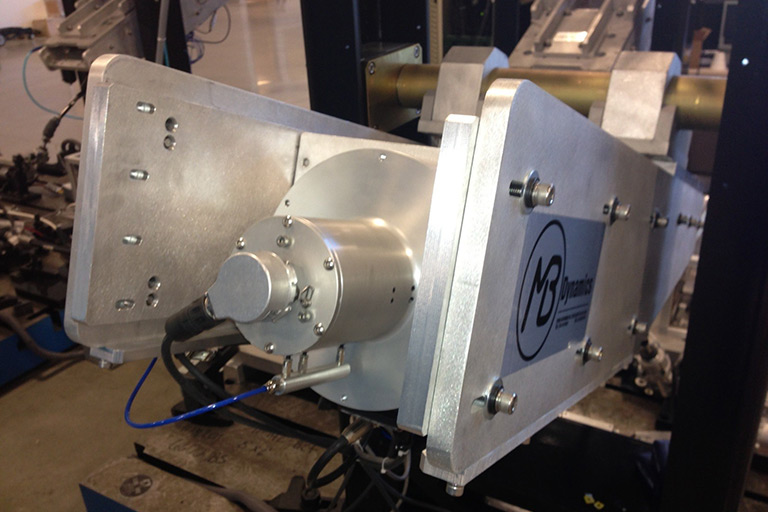

Simulates driver functionality by generating repeatable and precise steering maneuvers.

Quietly produces accurate, controlled, inputs to the in-vehicle steering wheel to enable acquisition of acoustic data and wheel motions

Electric, electrodynamic or pneumatic devices that apply programmable static, quasi-static and dynamic loads to one or both tie rods

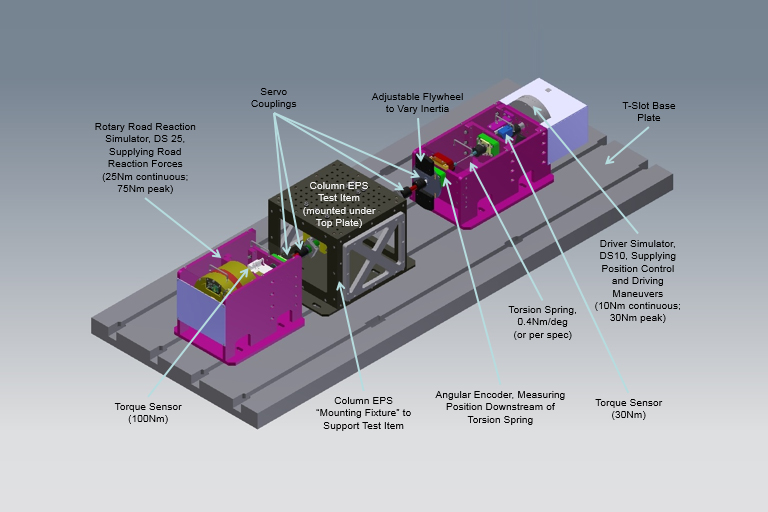

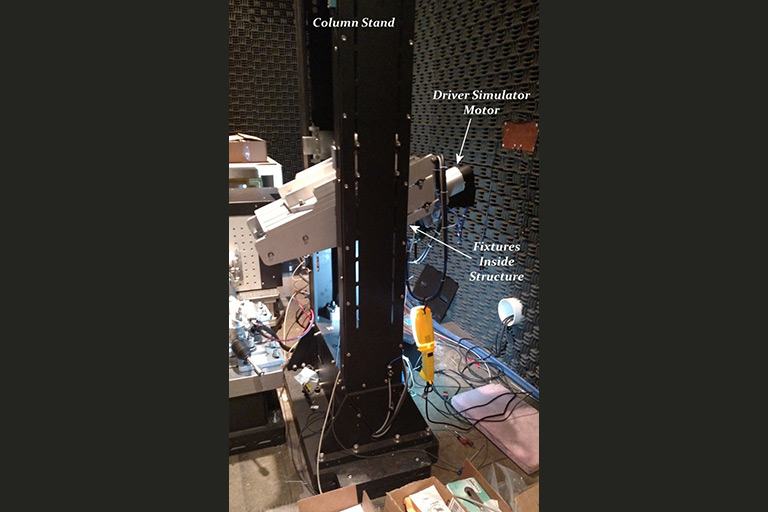

As a variant on a SMTS, our Column EPS Test Bench is a quiet, turnkey lab test system.

Used to evaluate stick-slip, lash, torsional stiffness, hysteresis and other performance characteristics.

Provides a column stand for mounting a steering column assembly, column EPS, and or a Driver Simulator.