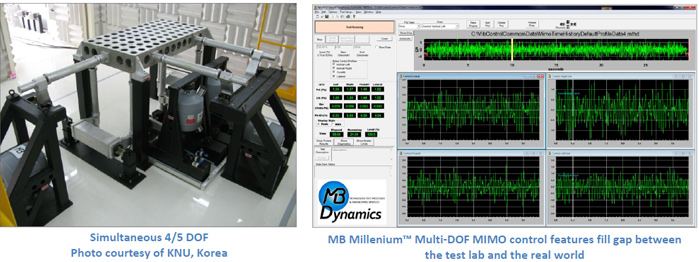

MB has announced its installation of its next-generation 4/5 DoF Squeak and Rattle System at Kongju National University (KNU), Advanced Motor Parts Regional Innovation Center, in Korea. Richard McCormick, president of MB Dynamics, states the System (pictured below) has been, “built quiet for squeak and rattle detection, powerful for S&R durability and multi-axis for realism. This is best-in-class quiet.” The MB Millenium™ MIMO controller replicates real-world squeak and rattle conditions within the laboratory environment. Features include:

- Simultaneous 4 DoF delivers 4 simultaneous axes of vibration controlled independently using 4 exciters: vertical, roll, fore-aft and lateral

- Simultaneous 4 DoF + Pitch is configured to deliver 5 axes with pitch coupled to fore-aft

- Excellent simultaneous reproduction of important DOFs for S&R: both time history replication and PSD random vibration

- Sequential 1-axis-at-a-time testing for diagnoses of S&R issues; conforms to GMW14011

- Very quiet, compared to hydraulic MAST; test equipment noise does not mask S&Rs

- Performs durability squeal and rattle tests on payloads up to 350 kg

- 4/5 DOF system is quiet and powerful enough for durability S&R; don’t need 2 different test systems

- Productivity advantages, shorter total test times, fewer hassles by not having to juggle test items on multiple test rigs

- Operates inside environmental chamber from -40°C to +50°C

- No hydraulics

Jun Yong-Du, PhD, Professor and Director of KNU’s Advanced Motor Parts Regional Innovation Center reports, “Our just installed 4/5 DOF BSR exciter suite is fantastically quiet and multi-functional. I believe this new MB system will contribute to fill the gap between the current test standards and the real world situation with its multi-DOF MIMO control features. The system will serve for Buzz, Squeak and Rattle (BSR) detection tests for seats and automobile interior parts/modules per GM, FORD and other global specifications and also for full vehicles through direct-body-excitation (DBE).”