MB PM-Series Shakers use permanent magnet technology and the voice coil principle to create vibration. These general-purpose shakers are heavy duty, industrial-quality equipment with a proven track record of lasting ten, fifteen, even over twenty years in demanding applications. You can buy “bargain basement” shakers or you can invest in MB PM-Shakers that will provide you with years of dependable, reliable, and consistent testing. Choose from five different sizes – depending on your needs – with maximum sine force ratings of 25, 50, 100, 250 or 500 pounds.

MB PM-Series Shakers use permanent magnet technology and the voice coil principle to create vibration. These general-purpose shakers are heavy duty, industrial-quality equipment with a proven track record of lasting ten, fifteen, even over twenty years in demanding applications. You can buy “bargain basement” shakers or you can invest in MB PM-Shakers that will provide you with years of dependable, reliable, and consistent testing. Choose from five different sizes – depending on your needs – with maximum sine force ratings of 25, 50, 100, 250 or 500 pounds.

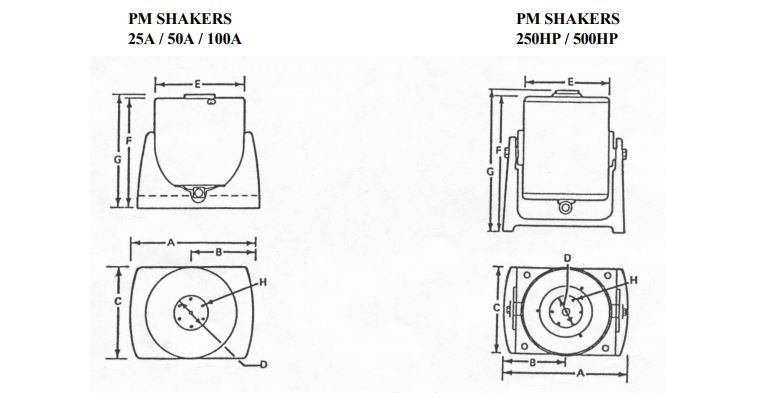

The PM25A, PM50A, and PM100A Shakers all have ½” stroke and a 2.7″ diameter mounting table. The PM250HP and PM500HP Shakers each have 2″ of stroke and a 4.1″ diameter mounting table.

MB Dynamics: Your Total Shaker System Supplier

MB delivers turnkey vibration test systems including PC-based Win2K10 vibration and shock controllers, MISO software or MIMO software, special-purpose fixtures, head expanders, oil-film slip table assemblies, horizontal moving tables with patented flexures, AGREE systems for combined environmental and vibration testing, data acquisition hardware & software, and vibration and acoustic instrumentation and signal conditioning.

PM-Series Maximum Ratings

| PM-Series Shakers | MB and P-Series Amplifiers | Force Ratings | Max Accel g’s pk |

SINE Velocity ips pk |

SHOCK Velocity ips pk |

30g 11ms Payload | Max Stroke in pk-pk |

Freq. Range Hz |

Armature | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Model | Coupling DC/Match | SINE lbs pk |

RANDOM lbs rms |

SHOCK lbs pk |

Res. Hz |

Wt lbs |

Bolt Circle inches |

Diam. inches |

||||||||

| PM500HP | PVL | DC | 500 | 250 | 500 | 80 | 55 | 55 | 10 | 2 | DC-3k | 2,800 | 6.2 | 3.5 | 4.1 | |

| PM250HP | MB1000VI | DC | 250 | 125 | 250 | 80 | 55 | 55 | 5 | 2 | DC-3.5k | 3,000 | 3.1 | 3.5 | 4.1 | |

| PM100A | MB500VI | DC | 100 | 50 | 100 | 106 | 70 | 70 | 2 | 0.5 | DC-7k | 6,000 | 0.94 | 2.25 | 2.7 | |

| PM50A | MB500VI | DC | 50 | 25 | 50 | 80 | 70 | 70 | 1 | 0.5 | DC-10k | 8,000 | 0.5 | 2.25 | 2.7 | |

| PM25A | MB500VI | DC | 25 | 12 | 25 | 50 | 70 | 70 | 0.3 | 0.5 | DC-10k | 8,000 | 0.5 | 2.25 | 2.7 | |

Download the PM-Series Shaker Data Sheet (PDF)

Performance Ratings

| Description | PM25A | PM50A | PM100A | PM250HP | PM500HP |

|---|---|---|---|---|---|

| Force Output | 25 pounds Pk* | 50 pounds Pk* | 100 pounds Pk* | 250 pounds Pk * | 500 pounds Pk* |

| Displacement | 0.5″ Pk -Pk | 0.5″ Pk -Pk | 0.5″ Pk -Pk | 2″ Pk-Pk | 2″ Pk-Pk |

| Velocity | 70 in/sec Pk | 70 in/sec Pk | 70 in/sec Pk | 60 in/sec Pk | 60 in/sec Pk |

| Acceleration (bare table) | 50 g Pk | 80 g Pk | 106 g Pk | 80 g Pk | 80 g Pk |

| Frequency Range | DC-10,000 Hz | DC-10,000 Hz | DC-7000 Hz | DC-3500 Hz | DC-3000 Hz |

| Cooling | 8 scfm @3″ H2O | 13 scfm @3″ H2O | 26 scfm @12″ H2O | 80 scfm @30″ H2O | 80 scfm @30″ H2O |

| Coil Current & Resistance |

4 amps; 2.7 ohms | 8.5 amps; 1.3 ohms | 8 amps; 2.6 ohms | 40 amps; 0.21 ohms | 38 amps; 0.5 ohms |

| Suspension Stiffness | 75 lbs/in | 75 lbs/in | 75 lbs/in | 40 lbs/in | 40 lbs/in |

| Stray Field – 1″ over center |

< 20gauss | < 7 gauss | < 8 gauss | < 40 gauss | < 20 gauss |

| DC Centering | Drives 25 lbs to 1″ Pk-Pk with 20% force derating |

Drives 50 lbs to 1″ Pk-Pk with 20% force derating |

Mechanical Specifications

| Description | PM25A | PM50A | PM100A | PM250HP | PM500HP |

|---|---|---|---|---|---|

| Mounting Surface Bolt Holes |

Six 10-32 threaded holes at 60o on 2.25″ bolt circle (+ center) |

Six 10-32 threaded holes at 60o on 2.25″ bolt circle (+ center) | Six 10-32 threaded holes at 60o on 2.25″ bolt circle (+ center) |

Six ¼x28 threaded holes at 60o on 3.50″ bolt circle (+ center) |

Six ¼x28 threaded holes at 60o on 3.50″ bolt circle (+ center) |

| Moving Element Diam. | 2.70″ | 2.70″ | 2.70″ | 4.10″ | 4.10″ |

| Base Footprint | 10″ x 7.5″ | 10″ x 7.5″ | 10″ x 7.5″ | 18″ x 14″ | 18″ x 14″ |

| Body Diameter | 7″ | 7″ | 7″ | 14¼” | 14¼” |

| Height (to table top) | 7½” | 9½” | 13½” | 17¼” | 20¼” |

| Moving Element Axial Resonance |

8200 Hz | 8000 Hz | 6000 Hz | 3000 Hz | 2800 Hz |

| Weight, Moving Element | 0.50 pounds | 0.62 pounds | 0.94 pounds | 2.6 pounds | 5.0 pounds |

| Weight, Exciter | 38 pounds | 55 pounds | 80 pounds | 250 pounds | 420 pounds |

| Weight, Base | 7 pounds | 11 pounds | 15 pounds | 25 pounds | 25 pounds |

| Base Type | 2-position; rigid | 2-position; rigid | 2-position; rigid | trunnion | Trunnion |

| Trunnion Base | optional | optional | optional | standard | Standard |

| Cooling Connections | 0.5″ NPT | 0.5″ NPT | 0.5″ NPT | 2.0″ port | 2.0″ port |

Dimensions

| Dimensions | A | B | C | D | E | F | G | H | Cooling |

|---|---|---|---|---|---|---|---|---|---|

| PM25A | 10″ | 5″ | 5 ½” | 2.25″ | 7-3/8″ | 7-7/32″ | 7-15/32″ | 10-32 | ½ NPT connection for cooling air 8 CFM at 3″ H2O |

| PM50A | 10″ | 5″ | 7 ½” | 2.25″ | 7-3/8″ | 9-7/32″ | 9-15/32″ | 10-32 | ½ NPT connection for cooling air 13 CFM at 4″ H2O |

| PM100A | 10″ | 5″ | 7 ½” | 2.25″ | 7-3/8″ | 13-7/32″ | 13-15/32″ | 10-32 | ½ NPT connection for cooling air 26 CFM at 12″ H2O |

| PM250HP | 18″ | 9″ | 14″ | 3.50″ | 14 ¼” | 14 ¼” | 17-3/16″ | ¼ – 28 | 2″ connection for cooling air 80 CFM |

| PM500HP | 18″ | 9″ | 14″ | 3.50″ | 14 ¼” | 19-3/4″ | 20-5/16″ | ¼ – 28 | 2″ connection for cooling air 80 CFM |