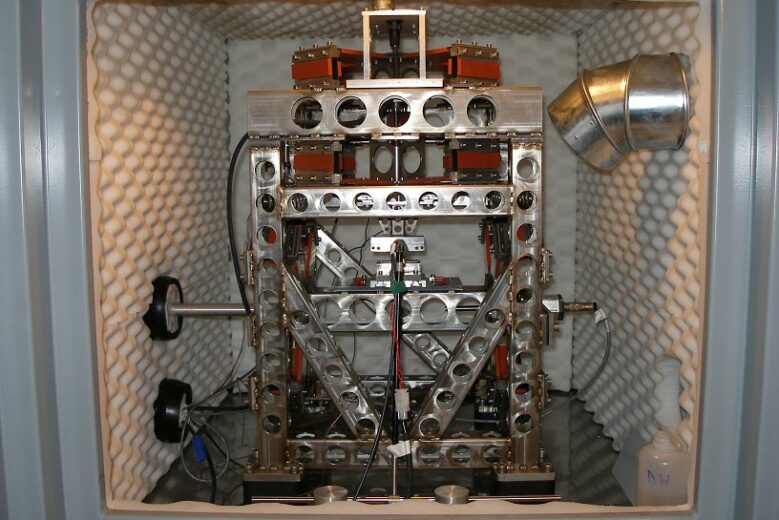

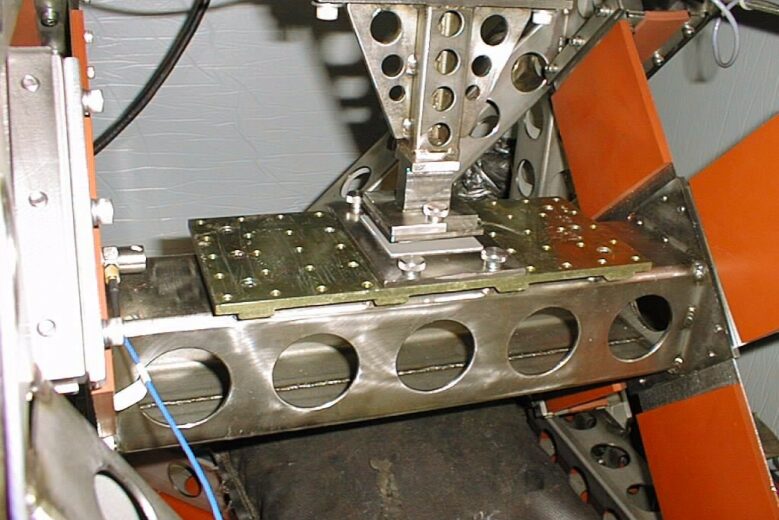

Automotive squeaks occur when materials in contact rub against one another causing annoying noises from friction-induced stick-slips. Automotive itches are a special category of squeaks that can develop when rubber or plastic rubs against glass or paint. The MB Dynamics Material Compatibility Squeak & Itch Test System (MCTS) is designed and manufactured to subject contacting pairs of materials and actual vehicle parts to precisely controlled interference & motion under in-vehicle environmental conditions in order to acquire, monitor, analyze and report friction and acoustic characteristics with the objective to:

- Better understand material compatibility,

- Find material combinations that perform best over a broad range of conditions.

- Troubleshoot existing squeak, itch and material compatibility problems.

- Evaluate effects of coatings; surface textures; material blends; adhesion between surfaces (stickiness); contaminants; oxides.

- Assess durability of coatings under various environmental and wear conditions.

- Evaluate surface asperity interactions; static/kinetic friction differences; contact oscillations normal to motion excited by surface roughness and waviness; tangential contact stiffness.

- Benchmark competitor material pairs.

- Correlate to friction math models to predict material compatibility performance.

- Identify material properties & system parameters that are good predictors of noise generation tendencies.

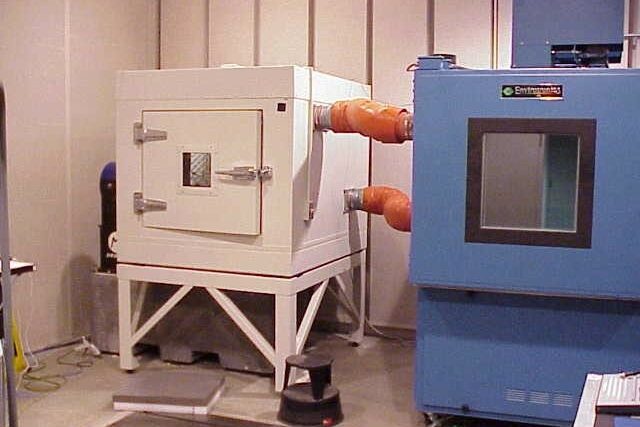

Controller software acquires, records and archives acoustic time histories (sound pressure and Zwicker loudness); normal force and friction force between materials during controlled motion; displacement, velocity, and acceleration from any controlled motion (sine, single excursion, PSD random, time history, relative accelerations between near mating vehicle components); interference or compression (negative gap between mating pairs); and temperature and humidity inside Quiet Chamber during a test. Quiet Chamber noise levels as low as 20 dB(A) and temperatures can range from -40°C to +85°C. Used to fulfill test procedures including GMW16321, GMW9842P, Ford CETP 01.07-L-400, and Ford CETP 01.11-L-400.

Material Compatibility Test System Data Sheet: Download PDF