Multi-Input, Multi-Output (MIMO) and Multi-Input, Single-Output (MISO)

The MB Millenium™ from MB Dynamics is a multiple-input, multiple-output (MIMO) and/or a multiple-input, single-output (MISO) dynamic test control system.

It reliably and accurately replicates actual end-user test conditions, including force, acceleration and motion control parameters, and can be used to control up to eight actuators, simultaneously or sequentially. The actuators are connected to a single test article that can be running independent force and/or vibration and motion profiles, whether synchronized or unsynchronized. Typical applications include time history replication, random vibration (PSD) control, and single- and multi-shaker sine with user-defined frequency and phase relationships.

The associated features and functionality of the MB Millenium dynamic test control system are borne from the company’s more than 80 years of know-how in vibration, shock and dynamic testing, both in-lab and in-field. System performance is further enhanced by the integration of commercially available, continuously evolving A/D and D/A hardware, with full engineering support available from National Instruments (NI), one of the industry’s most experienced teams.

The Eagle is the current platform in the MB Millenium family. It performs vibration control (acceleration and displacement), static and dynamic force control, linear and rotary motion control, and static and dynamic pneumatic control of test actuators and test functions. Each Eagle has one or more embedded controllers performing control functions, with analog and digital I/O provided by a variety of NI data acquisition and DIO boards. It uses either a customer- or MB-supplied Windows 10 desktop or tower PC for its graphical and user interface. The Windows 10 host is completely removed from all control processes running on the Eagle. As it operates as a non-networked, stand-alone unit, operation of the Eagle is therefore unaffected by Windows updates, IT security programs or corporate software.

The Eagle is the current platform in the MB Millenium family. It performs vibration control (acceleration and displacement), static and dynamic force control, linear and rotary motion control, and static and dynamic pneumatic control of test actuators and test functions. Each Eagle has one or more embedded controllers performing control functions, with analog and digital I/O provided by a variety of NI data acquisition and DIO boards. It uses either a customer- or MB-supplied Windows 10 desktop or tower PC for its graphical and user interface. The Windows 10 host is completely removed from all control processes running on the Eagle. As it operates as a non-networked, stand-alone unit, operation of the Eagle is therefore unaffected by Windows updates, IT security programs or corporate software.

The MB Millenium MIMO software is a natural continuation of the innovative, real-time signal processing work commenced by MB in the 1980’s, which includes under-constrained, noisy (non-Gaussian noise) multi-degree of freedom (DoF) dynamic systems. The proprietary techniques and algorithms incorporated into the MIMO implementation include impulse-response conditioning, time-domain feedback, and predictive noise-quelling. MIMO incorporates classic algorithms along with novel treatments. Its advanced software product development demonstrates the MB commitment to continuous improvements across its full family of vibration, force, and motion control products.

Datasheet Downloads:

NEW! MB Millenium Single and Multi-Axis Vibration and Motion Control System (PDF)

3-Axis Hand-Transmitted Vibration Simulator (PDF)

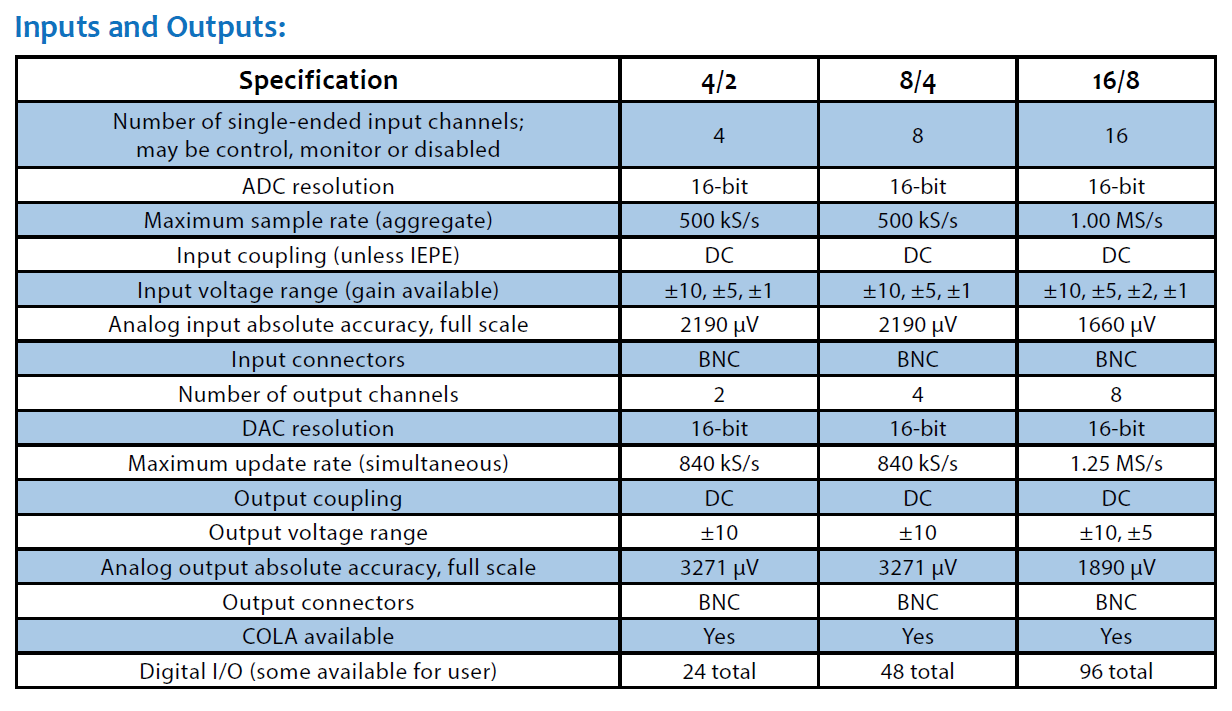

Inputs & Outputs

Specifications

● Static and dynamic control of up to 8 outputs, 16 inputs, and 8 individual actuators

● Supports electrodynamic, electromagnetic, pneumatic, and hydraulic actuators; linear and rotary motion control test systems; or subcomponents

● Supports acceleration, velocity, displacement, force, and motion profiles, with capability to mix profile types, in order to simulate a typical end-user environment

● Control applications include Time History, PSD Random, Sine, Classical Shock; MISO & MIMO

● Control bandwidth, MISO: ≤3.2 kHz (optional to 40 kHz); MIMO: ≤2 kHz; 200 Hz 6 DoF (7 shakers)

● Amplitude control accuracy: errors typically <5%

● Control loop time: 250 msec

● Sensor types: acceleration, angular position/rate, velocity, displacement, force, torque, encoder

● Inputs: AC- or DC-coupled voltage inputs or IEPE at 4 mA

● Anti-aliasing on input channels via multi-pole analog filters, oversampled ADC, and digital filters

● Rear-panel mounted BNCs for each channel – voltage or IEPE signal IN; DAC and COLA OUT

● Digital reconstruction filters on outputs provide >80 dB of rejection above max. control frequency

● Isolated outputs eliminate ground loops between controller and amplifier

● DIO functions: controller-initiated and externally-initiated commands to/from test equipment

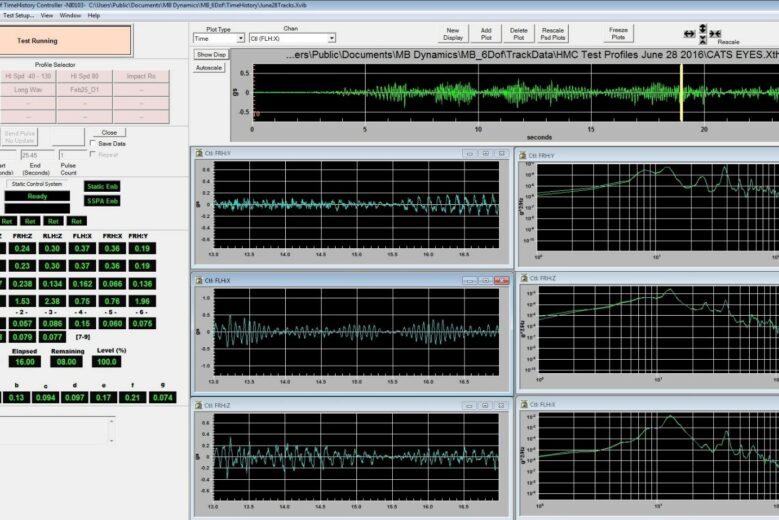

● Online display of actual control accuracy by comparing target excitation signal and resulting responses measured at the test item; time and frequency domain displays

● Import test profile data from Excel, TXT, ASCII and RPC-III (UFF); export test data to Excel

● Includes drive-file processing software for easy signal processing and integration of recorded road load data

● Optional software interface for REMOTE control or integration into superimposed test bench

control for execution of automated test sequences

● Test sequencing or scheduling available (mission profiles)

● User-adjustable amplitude control during a test

● English or metric units

● Data saved, during and automatically at end of test; can be post-processed or printed at any time

● Simultaneous compensation for cross-coupled dynamic responses from multiple actuators

● Random Vibration Notching and Sine Notching based on separate profile(s)

● Skewness, Kurtosis and Crest Factor control available

● Coordinate transforms

● Time-domain and frequency domain adaptation

Safety

● E-STOP mounted to amplifier front panel and remote at user station; gentle shutdown when activated

● Pre-test controlled and limited to maximum pretest level, assures drive waveform is compared to response; error-checks test conditions; protects shakers by comparing test profiles to shaker limits

● Continuous loop check for safety & protection, minimizes risks due to faulty cables & test equipment

● Shutdown on open loop, loss of control signal, exceedance of abort and RMS level

Physicals

● Input power: 100 – 120 VAC, 208 – 240 VAC (selectable) 47 – 63 Hz, 1-phase, <1 kVA

● Dimensions and weights:

o 4- and 8-channel: 19” wide (rack mount) x 20.25” (514 mm) deep x 4U (7” or 178 mm); 12 kg

o 16-channel: 19” wide (rack mount) x 20.25” (514 mm) deep x two 4U (14” or 356 mm); 20 kg

● Operating temperature range: 0°C to +50°C

● Operating humidity range: 10% to 90%, non-condensing