Industry-Exclusive Design Excites Sine Forces Up to 4000N

April 3, 2019 – Cleveland, Ohio, USA – MB Dynamics, Inc. (www.mbdynamics.com) (MB), field-proven industry experts in the design, manufacture and supply of vibration test systems and equipment, including buzz, squeak and rattle (BSR), steering, and suspension component test systems; modal exciters and amplifiers; automated calibration systems; dynamic controllers; transducer calibration systems; and engineering services, has announced its Modal 1000 exciter system for large-scale modal and structural testing.

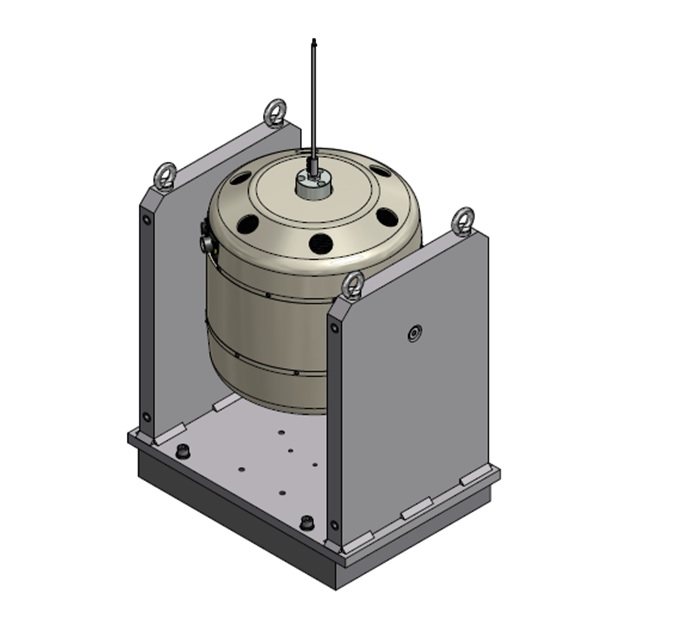

The MB Modal 1000 can excite sine forces of up to 4000N (900 lbf), with a 2-inch (50 mm) peak-to-peak stroke and 1. 5 m/s peak velocity (60 inches per second), at frequencies from DC to 2000 Hz. Both thermal shutdown protection and over-travel control are provided as standard features on this model.

The unique armature design of the MB Modal 1000 incorporates a “weak” suspension. The suspension may be fine-positioned to the test article using DC current. This is a particularly useful feature within lower-frequency response applications, such as ground vibration testing, where a DC-coupled exciter/amplifier may be in use. The armature’s lower weight further minimizes mass loading effects on the test article while reducing force drop-off at resonance. This avoids test article contamination during parameter extractions at each natural frequency. Additionally, the use of weak suspension means that the armature applies no extra force. Exciter dynamics are therefore de-coupled from measured test article dynamics for improved measurement data integrity.

The MB Modal 1000 exciter system may be used as either a stand-alone unit or paired with an MB P-Series power amplifier. The amplifier is housed within a 750 mm high, 19-inch rack cabinet and operates from 208-240V AC single-phase power. Supporting stingers, used to apply forces to the test article without exciter interference, are also available, measuring hex rod x 400 mm long with ¼-28 threads on each end.

Beyond its unique standard features, the MB Modal 1000 exciter system is offered with several customization options. Among them, the end-user capability to operate supporting amplifiers directly from a PC, allowing for amplifier positioning closer to the exciters. Test reliability is therefore improved, as drive cable lengths are minimized, with reduced risks of diminished force outputs caused by cable voltage drops. Also available is an optional automated ON/OFF exciter cooling package. Here, the cooling package engages only when the exciter heats up, in direct response to increasing levels of requested modal excitation forces. This protects the exciter from overheating, a particularly useful feature when end-users must oversee multiple test setups. As the package only engages when necessary, energy requirements of both the exciter and cooling package are optimized. The cooling package may be further specified with an optional <60 dBA Quiet Enclosure. Other optional accessories include piezoelectric force sensors to 4448 N (1000 lbs.), in tension and compression modes, with 5 mV/lb. (1.1 mV/N) sensitivities; and a supporting accessory kit. Full engineering consulting support is also available upon request, with all services provided by recognized industry experts of more than 35 years.

Typical applications for the MB Modal 1000 exciter system include structural damage detection; larger-scale advanced structural dynamics investigations, of buildings, bridges and commercial aircraft; aerospace ground vibration testing; large-scale experimental modal analysis, incorporating MIMO, MISO, SISO and SIMO techniques; FEM correlation and validation; and smaller-scale structural testing with higher-level vibration inputs.

For more information about the Modal 1000 exciter system, or other MB products and services, please contact MB at +1-216-292-5850, via email at [email protected], or visit www.mbdynamics.com.

PR Author:

Molly Bakewell Chamberlin

President / Industry Subject Matter Expert

About MB Dynamics, Inc.

Founded in 1939, the privately held, Cleveland, Ohio-based MB Dynamics has long distinguished itself as a total solutions provider for vibration test requirements. The company applies its vast wealth of experience in vibration testing and instrumentation to offer a truly one-of-a-kind innovative approach to customer problem-solving in automotive, aerospace, industrial, laboratory R&D, civil engineering, modal and structural testing, general test and measurement, academia, and other sectors. All solutions offered by MB Dynamics are further accompanied by the necessary hardware and software to ensure seamless integration, along with the value-added benefits of full engineering support, offered by one of the industry’s most experienced engineering teams. This expertise is made available to MB Dynamics customers locally in more than a dozen countries. Visit www.mbdynamics.com to learn more.